جوشکاری گدازی روشی مشابه با لحیم کاری است با این تفاوت که مواد تحت اتصال نیز ذوب می شوند. در این روش، ماده پرکننده ذوب شده و سپس به درز اتصال منتقل می شود. معمولاً جنس ماده پرکننده مشابه با مواد تحت اتصال است، بنابراین هنگامی که ماده پرکننده مذاب وارد درز اتصال می شود، مقداری از حرارت خود را به مواد تحت اتصال منتقل می کند و باعث ذوب آن ها می شود. به همین دلیل، این روش جزء روش های جوشکاری ذوبی (fusion welding) محسوب می شود. در لحیم کاری، ماده پرکننده (لحیم) نقطه ذوب پایین تری نسبت به مواد تحت اتصال دارد و حرارت لازم برای ذوب آن موجب ذوب مواد تحت اتصال نمی شود. [,a;hvd

A welding process in which coalescence is produced by heating with molten filler metal, which is poured over the joint until the welding temperature is attained and the required amount of filler metal is added.

In principle, one of the simplest ways of joining two metal surfaces is to flow

liquid metal between them and allow it to solidify. There are significant

advantages to be gained from such a procedure. There is no bulk melting,

distortion is minimized, and the thermal cycle is relatively benign. Two essential

requirements must be met if a satisfactory joint is to be made in this way. Firstly,

as noted in Chapter 1, the temperature of the solid at the solid-liquid interface

must be at least equal to the melting point of the liquid. Secondly, there must be

some means of removing the oxide film on the surface of the solid so that the

liquid can bond to a clean metal surface.

There are three variants of this method: flow welding, brazing and soldering. In

flow welding the composition and melting point of the liquid phase are similar to

those of the solid, and the interface is heated to the required temperature by

conduction and convection from the liquid. Flow welding processes are described

in Chapter 6. The remainder of this chapter is concerned with the brazing and

soldering of metals. The use of such processes for joining non-metallic solids to

themselves and to metals is covered in the next chapter.

The earliest fusion welding technique, mentioned briefly in the previous chapter,

known as flow welding or burning together, has been practised since the early

Bronze Age. A mould is made around the two bronze parts to be joined, and

molten bronze is poured between and sometimes around them. This method was

used for repairing swords and it was also employed for the fabrication of a

bronze chariot discovered in 1980 near the tomb of the Chinese Emperor Qin Shi

Huang. As practised in earlier times, this was an unreliable process; nevertheless,

some of the welds in Emperor Qin’s chariot remained intact when it was dug up

after two millennia.

Flow welding is used to this day, in the form of thermit welding for joining

rails in situ. A mould is set up around the rail ends with a crucible on top

containing a mixture of iron oxide and aluminium powders. The rails are

preheated to about 500 C, then the thermit mixture is ignited, producing highly

superheated steel. This melts through a plug in the base of the crucible, flows

into the cavity between the rails and makes a weld. A similar technique is

employed for joining copper power cables in the field. Sound, reliable joints are

obtained using the thermit process.

Ref.: J. F. Lancaster, “Metallurgy of Welding”, Springer

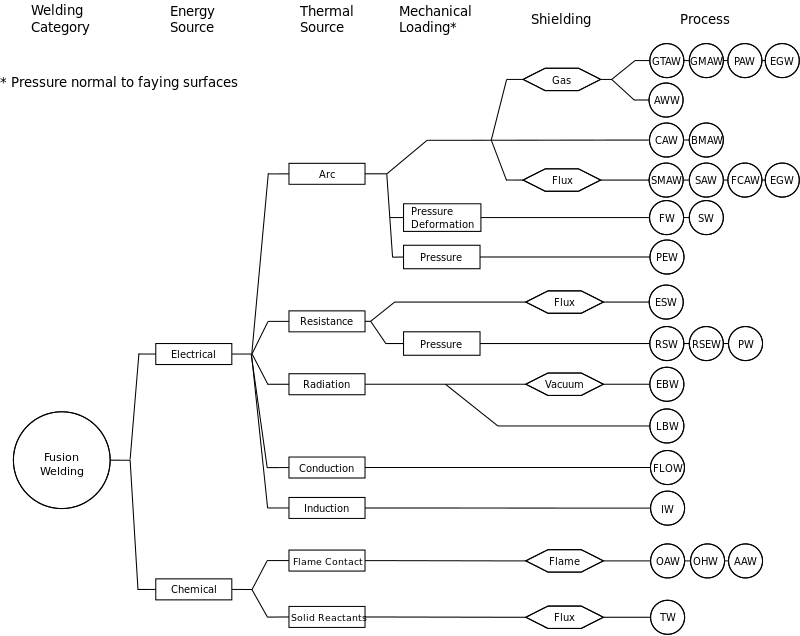

Gas Tungsten Arc Welding (GTAW), TIG

Gas Metal Arc Welding (GMAW): Metal Inert Gas welding (MIG) , Metal Active Gas Welding (MAG)

Plasma Arc Welding (PAW)

ElectroGas Welding (EGW)

Carbon Arc Welding (CAW)

Bare Metal Arc Welding (BMAW)

Shielded Metal Arc Welding (SMAW)

Submerged Arc Welding (SAW)

Flux-Cored Arc Welding (FCAW or FCA)

Flash Welding (FW)

Stud Welding (SW)

PErcussion Welding (PEW)

Electroslag welding (ESW)

Resistance Spot Welding (RSW)

Resistance SEam Welding (RSEW)

Projection Welding (PW)

Electron-Beam Welding (EBW)

Laser Beam Welding (LBW)

FLOW Welding (FLOW)

Induction welding (IW)

OxyAcetylene Welding (OAW)

OxyHydrogen Welding (OHW)

Air Acetylene Welding (AAW)

Thermite Welding (TW)