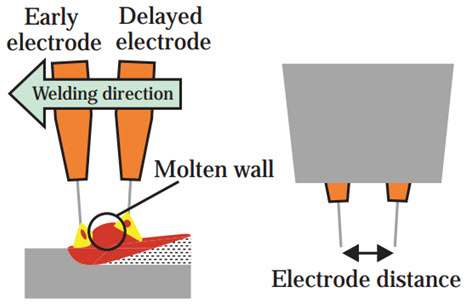

جوشکاری تاندِم یا دوپشته، نوعی روش جوشکاری است که در آن، دو پاسه جوش بهطور همزمان ایجاد میشوند. برای مثال، میتوان فرض کرد که دو الکترود با فاصلهای کم از هم قرار گرفتهاند و پشت سرهم در درز اتصال حرکت داده میشوند؛ الکترودی که جلوتر است، پاسه زیرین را و الکترودی که پشت آن قرار گرفتهاست پاسه رویی را ایجاد میکند. مهمترین جذابیت این تکنیک آن است که با یک حرکتِ رفت، میتوان جوشی با نفوذِ بالا در عمق و پهنای زیاد در سطح ایجاد کرد. پس واضح است که پارامترهای جوشکاری باید بهگونهای انتخاب شود که الکترود جلویی، جوشی با عمق نفوذ بالاتر ایجاد کند و الکترود عقبی، جوشی با پهنای بیشتر.

البته باید توجه داشت که جوشکاری دو پشته به روشهای قوسی خلاصه نمیشود. ترکیبی از روشهای مختلف میتواند استفاده شود، برای مثال جوش جلویی از نوع لیزر باشد و جوشی که بهدنبال آن میآید از نوع GMAW. تعدادی از روشهای دوپشته در ادامه آمده است.

Tandem-pulsed gas metal arc welding

Tandem arc welding

Tandem gas metal arc welding

Hybrid tandem metal active gas welding

Tandem TIG welding

Tandem-Pulsed Gas Metal Arc Welding

Tandem GMAW

Tandem double-wire MIG welding

Tandem Submerged Arc Welding

Tandem Mig/Mag Welding

Tandem pulsed gas metal arc welding

Single arc welding system, and tandem arc welding system

TANDEM and GMAW twin wire welding

Tandem electron beam welding

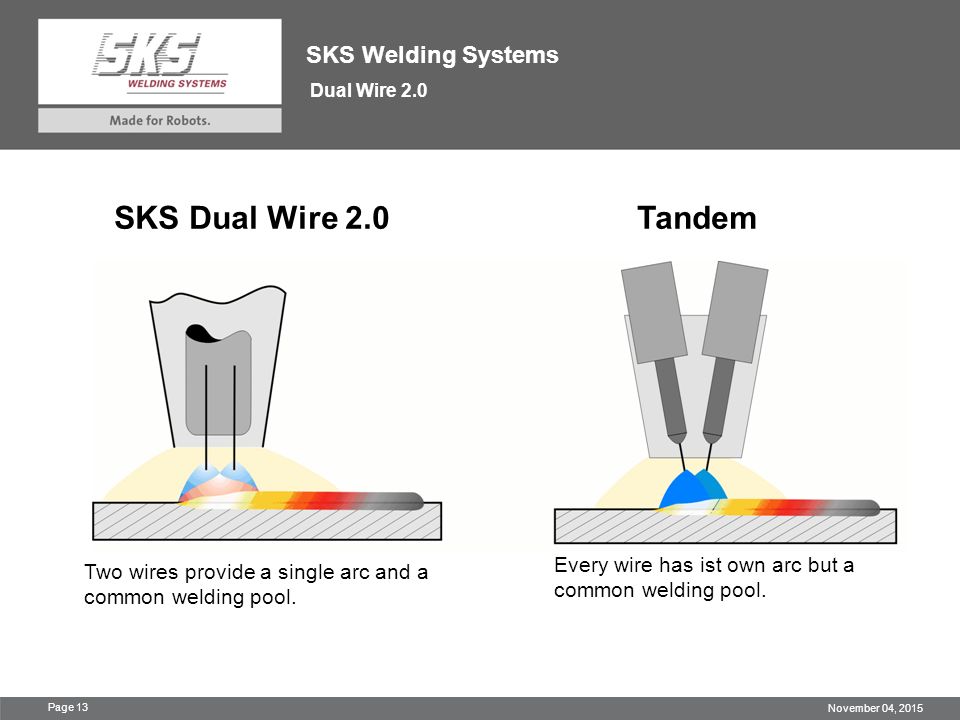

این تکنیک نباید با روش SKS اشتباه گرفته شود. در روش SKS یا Dual wire نیز دو سیم جوش همزمان به محل جوش تغذیه میشوند با این تفاوت که، در این روش، هر دو سیم تحت یک قوس ذوب میشوند. اما در روش Tandem، هر الکترود، یک قوس مجزا ایجاد میکند. البته بهعلت نزدیک قوسها، گاز محافظ در هر دو روش SKS و Tandem میتواند از یک نازل تأمین شود. کلیپی از روش دوپشته به همراه چند تصویر در ادامه آمده است.

What is … tandem welding?

Tandem welding represents a milestone in the history of gas metal arc welding (GMAW). Perfect welding quality and high productivity were key considerations in its development, since welding processes that fulfill these conditions are increasingly in demand.

But, what exactly is tandem welding? What advantages does the process offer and where is it used? How does it differ from double-wire welding?

Basics

The process involves high performance MIG/MAG welding using two wire electrodes. It is only used in fully automated (robot) applications, and is ideal for increasing welding speed as well as deposition rate. So how does it work?

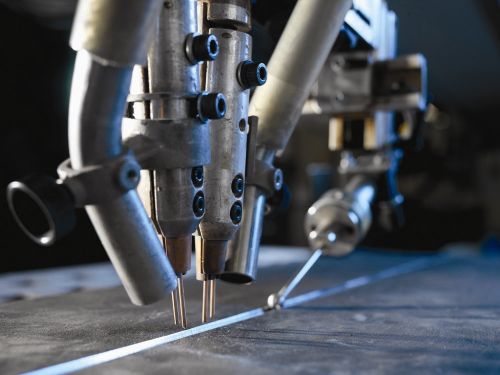

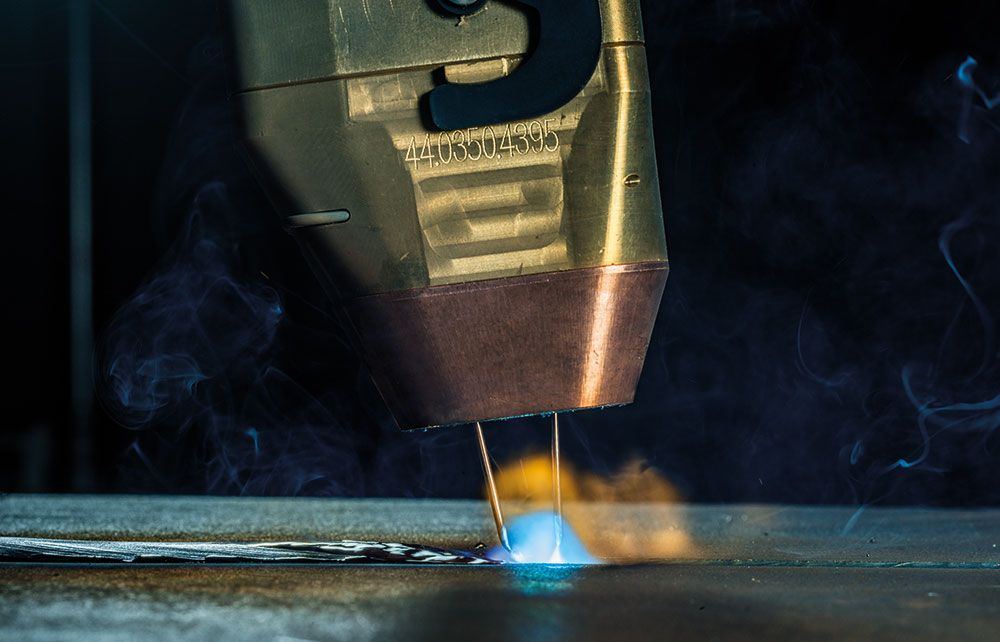

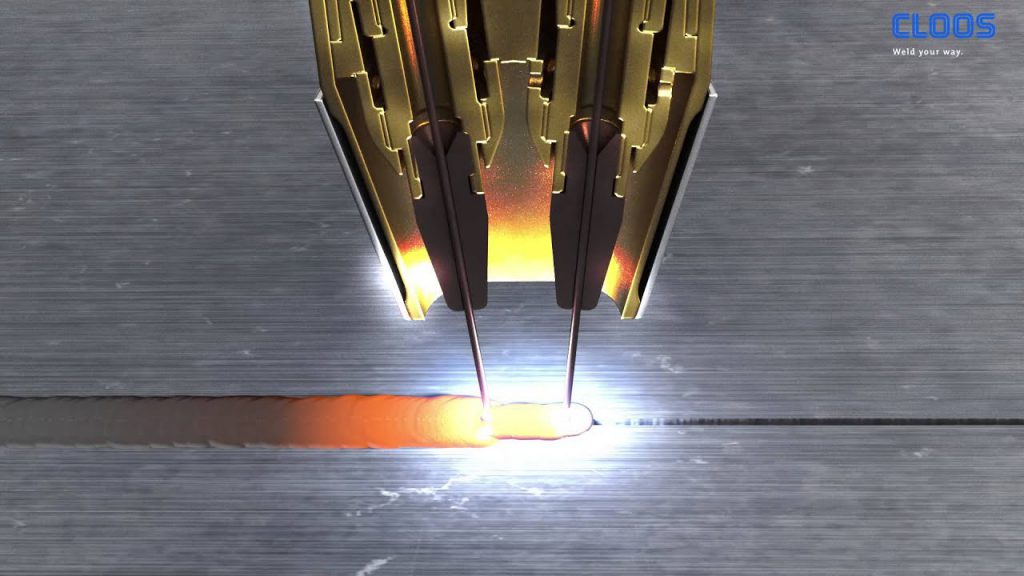

During tandem welding two wire electrodes are melted at the same time. These are routed through two electrically isolated contact tips, i.e., the potentials are separate. As a result, the arcs can be controlled independently and, despite differing outputs, can be precisely coordinated.

Differences between Double-Wire and Tandem Welding

Double-wire welding represents the very beginnings of welding using two wire electrodes (developed at Fronius around 25 years ago). Here, electrodes with the same potential (not electrically isolated) were used. These could either be fed into one single or two separate contact tips.

The disadvantages:

At the time of double-wire welding there were no suitable characteristics such as pulse or PMC (groundbreaking developments). Standard welding in the dip transfer arc used back then led to increased formation of welding spatter, which resulted in instability of the arc and fluctuating arc lengths. This produced other drawbacks in the process (e.g., adhesion of spatter on contact tip and gas nozzle).

Tandem Welding in Detail

Tandem welding is based on two independent welding systems that are synchronized with one another. The separate wire electrodes are fed into a single torch hosepack via separate wirefeeders – with a single gas nozzle and electrically isolated contact tips. Two arcs generate a single weld pool.

Both wire electrodes can be synchronized accordingly using a Twin Controller: start, phase shift of the material transfer (simultaneous control of droplet detachment is not possible without phase shift), etc. In addition, a wire electrode can be connected or disconnected. Welding can be performed in both directions.

This results in a high degree of flexibility: the process is much more stable allowing very high welding speeds (2 m/min +) to be achieved on thin sheets. For thick sheets, the process boasts a high deposition rate (22 kg/h +), which allows a significantly higher weld seam volume to be achieved.

The Advantages of Tandem Welding at a Glance

/ Two separate contact tips à each contact tip can be controlled independently

/ Extremely high welding speeds (2 m/min +, depending on the welding position)

/ Extremely high deposition rate (22 kg/h +)

/ Can be used on thin and thick sheets

/ High potential for cost savings

/ Easy to operate

/ Different wire feed speeds possible between the lead (front) and trail (rear) wire electrode

/ Synchronizing of both arcs promotes process stability

Application Areas

The process is highly versatile due to the high degree of flexibility and overall advantages. As such tandem welding has applications in the following industries: Yellow Goods (construction machinery), Commercial Transport (vehicle and rail vehicle construction), Automotive Industry (supply industry), and General Industry (container construction).

Examples: Welding in the construction machinery sector brings its own challenges. It is often necessary to switch between single wire and tandem welding: this can be done by swapping the torch body or simply disconnecting an electrode. This enables difficult to access parts to be welded, for example.

Welding challenges in the field of rail vehicle construction can also be addressed appropriately: in particular for the floor, wall, and roof structures of high-speed trains, very high welding speeds (extremely long weld seams) are required. Moreover, extruded profiles (usually made from aluminum) need to be joined with the least possible distortion, and the visible weld seams must represent outstanding quality – another benefit of the tandem process.